Search Vendors nearby...

Hybrid Solar Water Pump (AC + DC Compatible)

Runs on Solar by Day. EB Power by Night. Zero Interruption.

- Save electricity upto 60 - 80%

- No inverter. No battery.

- Smart automatic power switching (AC<->DC)

Ideal for Apartments, Farmhouses & Commercial Buildings

- Save electricity upto 60 - 80%

- No inverter. No battery.

- Smart automatic power switching (AC<->DC)

Ideal for Apartments, Farmhouses & Commercial Buildings

Bore Well Submersible Pump

Surface Well Piston type Jet Pump

Bore Well Compressor Pump

Pressure booster by flow Switch control

Booster Pump (w/o Tank)

Booster Pressure Pump (1 litre tank)

Booster Pump with 20 / 24 litre tank

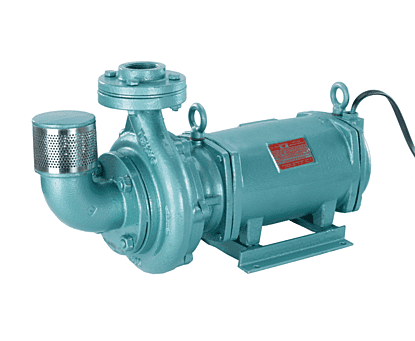

Open Well (Horizontal) Submersible Pump

Open Well (Vertical) Submersible Pump

“Need help choosing a pump? Talk to an expert now.”

Pump Selector

Best Water Pumps for Home & Commercial Use - PlumbingStores.in

Find the Right Water Pump for Your Needs

Looking for reliable and efficient water pumps for your home, agriculture, or industrial use? At PlumbingStores.in, we offer a vast selection of high-performance pumps to meet all your water management requirements. Whether you need a monoblock pump, submersible pump, or booster pump, we have you covered with top-rated brands at competitive prices.

Why Choose PlumbingStores.in for Water Pumps?

Wide Range of Brands – We feature top brands like Texmo, Kirloskar, Crompton, CRI, Lubi, V-Guard and more.

Competitive Pricing – Get the best deals on high-quality pumps with price comparisons.

Expert Advice – Need help choosing the right pump? Our experts are here to guide you.

Easy Online Shopping – Enjoy a seamless shopping experience with secure payments and quick delivery.

Genuine Products & Warranty – All our pumps come with a manufacturer warranty for reliability and peace of mind.

Product Catalogue — Select an option

Share My Location

Click the button below to share your current location via WhatsApp:

Our Rates

This is a great place to let your visitors know who you are. Add useful information that your users may find interesting.

Shop Water Pumps Online - Fast Delivery Across Chennai

At PlumbingStores.in, we ensure hassle-free delivery across Chennai so you can get your pump delivered to your doorstep quickly. Whether you need a residential water pump, farm irrigation pump, or industrial pump, we have a solution for you.